China Top Solenoid Coil Manufacturer

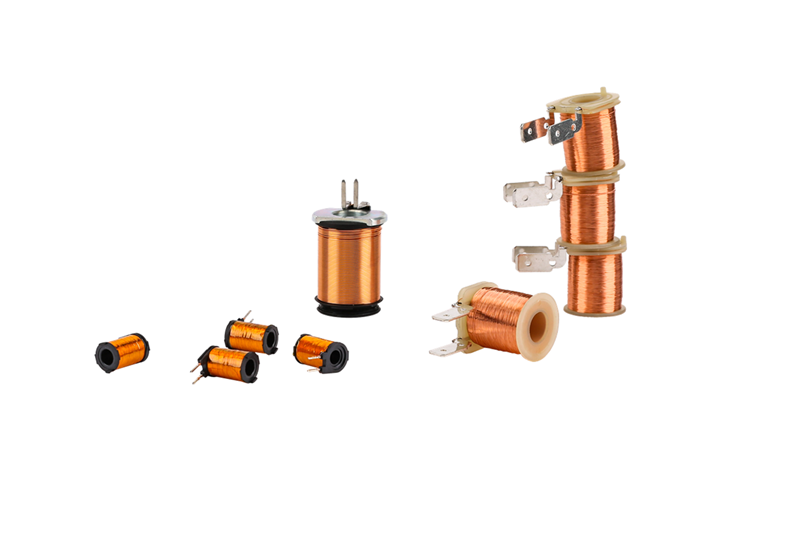

Beris Electronic offers a complete range of solenoid valve coils, which designed into various types, mainly features encapsulated coils, including thermoplastic and thermosetting. We also provide excellent Customized service.

Our coils have the characteristics of high performance, high reliability and long service life, can be used for different applications.

Beris valve coils is designed and manufactured according to EN 60204.1 and VDE 0580 and suitable for industrial ambient conditions. For use in different ambient with high humidity or temperature, and different electrical connections are available.

Features of Beris Valve Coils:

- Heat resistant bobbin moulded with thermoplastic polyester material

- High quality Enameled copper wire, F,H,N different insulation class for choose

- Built-in magnetic yoke, made by low carbon iron

- Encapsulation with high quality specially designed thermosetting & thermoplastic material.

Main structure:

The conventional structure of a solenoid valve coil includes: Framework, Enameled copper wire, PIN, Yoke and Encapsulation. In addition, according to the actual use, there will be a magnetizing guide ring, a rectifier bridge be used for rectifying, etc.

Some special design with flux ring to enhance the electromagnetic performance.

Enameled copper wire:

Copper conductor with a coat of insulating paint on its surface, which is the core material of the Solenoid valve coil. Solenoid coils used in valves are designed and tested for continuous service. They all meet the thermal endurance specifications according to IEC 216

Bobbin:

The bobbin is the carrier of enameled wire winding. According to the temperature rise of the valve coils and the actual use environment, different bobbin materials are selected, such as PA66, PPS, PBT, PET etc., and a few of them are thermosetting BMC and PT-310

Pin:

The function of the pin is to realize the electrical connection between the internal enameled wire and the outside, similar to the same role are terminals, flying leads and so on. Pin material is generally brass, such as H59, H62, H65, of which H62 is the most.

Yoke:

It is used to gather the magnetic field lines from the N pole to the S pole, increase the magnetic field strength and minimize the magnetic leakage into the air. A reasonable yoke structure design is conducive to improving the magnetic field strength. Generally, there are two kinds of yoke materials: low carbon steel cold-rolled plate and electrical pure iron (DT4C).

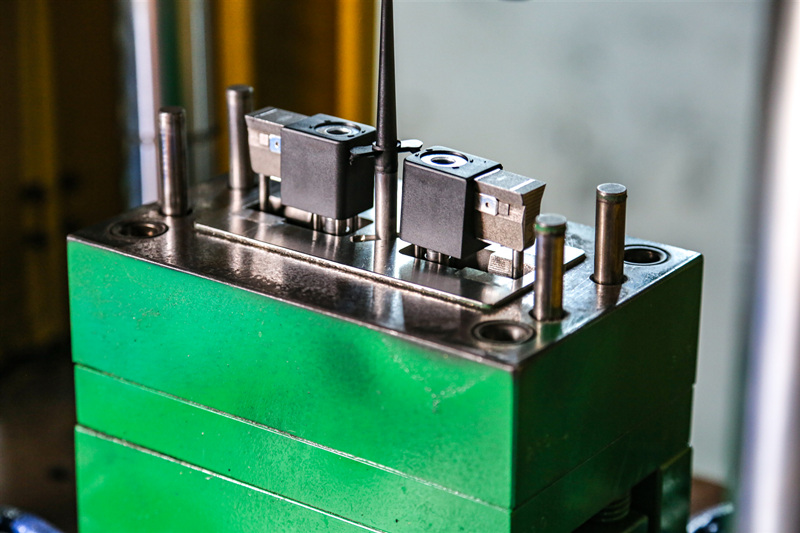

Encapsulation:

It is used to combine the solenoid coil parts into a whole, which plays a role of waterproof and dustproof. The materials include thermosetting and thermoplastic.

How to choose a suitable high-quality solenoid coil?

When it is necessary to select a suitable solenoid valve coil for a solenoid valve, Beris team recommends to consider from four aspects, They are matching, reliability, safety, and economy.

1. Matching

Matching refers to whether the performance and structure of the solenoid coil can match the use requirements of the corresponding solenoid valve.

If some performance parameters do not meet or exceed the standard, the solenoid valve may be damaged or not work properly; in addition, the structure is unreasonable, which may result in the failure to install or the installation is not in place, and the solenoid valve may not be used normally.

In terms of performance, we mainly consider these parameters of Solenoid valve coils:

- Working voltage

The first thing to consider is the type and size of the power supply voltage of the solenoid valve, which is DC or AC.

If it is AC voltage, the frequency needs to be provided, because the same coil 50Hz and 60Hz power difference is about 1.2 times, such as: 50Hz use 7.2W, 60Hz use about 6.0W; 50Hz coil uses 60Hz, the voltage difference is about 1.095times, such as AC220V 50Hz and AC240V 60Hz coil is universal

For more details about difference of AC and DC voltage, please check our special page introduction ... link

- Supply power or resistance

- Outer diameter and height of the solenoid armature or solenoid valve coil’s aperture and height

- Working environment: temperature, humidity, indoor or outdoor, protection grade

- Connection with external power supply: pin type, flying leading type, standard interface, etc.

- Application areas: Some special application areas require the use of specially designed Solenoid coils. Different general applications, such as industries that require waterproof, must use IP67 or higher grade solenoid valve coils.

- Other requirements: such as environmental protection material requirements or certification

2. Reliability:

First of all, please choose the solenoid valve coil made by a professional manufacturer, secondly, choose the higher quality grade, its reliability is relatively high.

Beris Electronic, not only provide high-quality electromagnetic coils, but also provide systematic solutions

3. Safety

We must focus on whether the selected solenoid coil matches the use environment of the solenoid valve, especially the special use environment,

- Waterproof solenoid coils must be used in environments with waterproof conditions, such as solenoid valves for outdoor use or fountains, etc.

- Explosion-proof products must be selected for explosive environments.

- The maximum nominal pressure of the solenoid valve coil calibration must exceed the maximum pressure in the pipeline, otherwise the service life will be shortened or other unexpected situations will occur.

4. Economy

In many cases, the solenoid valve coil can be universal, but try to choose the most economical product on the basis of meeting the above three points, to save costs. Beris Electronic will provide you with various types of solenoid coils with the best cost - effective performance

If you are still not sure what kind of valve coil is suitable for you, please contact our expert team directly, we will provide you with professional advice in the shortest time.

More Information